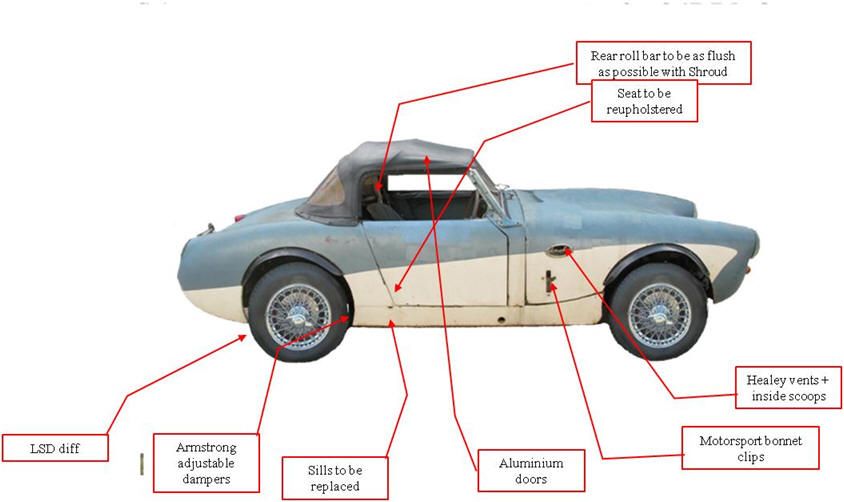

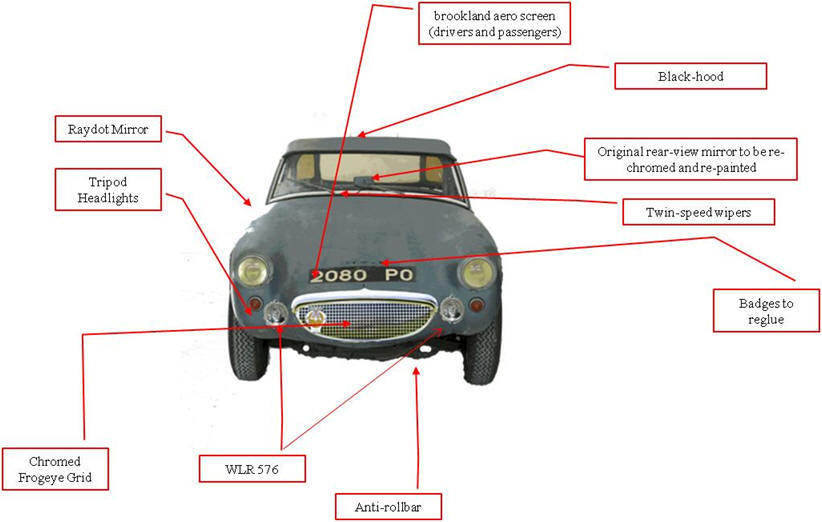

Clearly there is a little bit of T.L.C to be delivered

before 2080 PO can be driven again. Restoration can be a tricky business

as it generates many questions on what the end product

should be as well as providing vast ground for

costly errors. Should the car be restored as it was when last driven ?

Should it be put back as when first raced ? should one use only period

spares or compromise ? Will it be a race car or a fast road car ? who

can I entrust to do the work ? etc... etc...The list is never ending...I

have now spent quite a few weeks researching the car as well as another

one which I intend to build as an FIA car to do the Monaco, but more on

that one later...Anyhow though there is still some degree of

uncertainties I seem to have answered most of my questions and concluded

as follows: I will restore 2080 PO to its former racing glory in a

sympathetic manner without being ultra-orthodox about details. Clearly I

intend to re-use as much as possible of the car but will be pragmatic

about it and put safety before age and beauty. I want to use the car for

track days and possibly at a later day in competitive events but

also enjoy it on the odd English country lane from time to time. Acknowledging my mechanic skill are somehow limited I have enrolled the help of Andrew Forster at Archers

Garage in Birmingham. Probably the best one can hope for in terms of

experience and skills. The below will illustrate the restoration and be populated as a function of the

progress made ....so I am afraid you will have to visit the site for

quite a few months before seeing the end result....

|

|

2080 PO arrives at the farm in Sussex and

trigger much interest from the locals.... |

|

|

The car get in its temporary residence |

|

|

I cant wait for it to be roadworthy again, its

going be so much fun ! |

|

|

Reacquainting myself with the use of a spanner... |

|

|

Ready to be collected for its spa treatment by

Andrew...Not bad for a few weekends laboring.... |

|

|

Best Mecano set I ever had...though i am

missing a few bits... |

|

|

Can you see it ? Definitively has the racing

look ! |

|

|

Just a little be more T.L.C and we are ready for

Goodwood... |

|

|

On the 20th of July some of the joy of

re-chroming hit home...

The difference it brought to the vents was

quite amazing...whilst it preserved some of the nook and

crannies...

I was nearly tempted to keep the old

patina...but the chrome looked good and I can always park the

car under the rain...for another 50 years to get it back....

The company that did the work can be found at :

http://www.chromefix.co.uk/ , all I can say is excellent

door to door service and reasonable pricing... |

|

|

|

|

|

|

What at difference ! The steering wheel was

restored by

Car Wood Restoration. The service was excellent just

dispatch the wheel , agree on the price wait a week or so and

receive the transformed item for a very reasonable

price....I

definitively recommend them. |

|

|

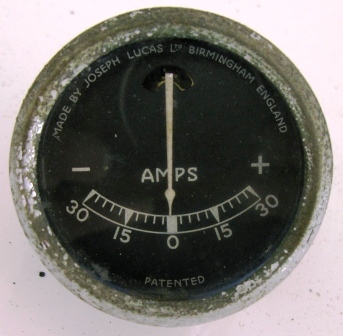

All the gauges were preserved and sent to

Speedograph

in Nottingham who restored them. They repainted the casings,

changed the chrome rims (but for the exception of the ammeter) ,

replaced the sensors for the oil and water temperature gauges. I

asked them not to repaint the face of the instruments so to keep

the old patina. Overall I was fairly impressed by the result and

the speed of the service (3 weeks). the cost seemed reasonable

at around 50 pounds per gauge. I definitively recommend them.

Finally all gauges are now guaranteed for 12-month. The only

issue is that they do not specialize in the type of tachometer i

had so i polished it myself and hope the inners are still in

good condition...i guess we will see when we get the engine....

|

|

|

|

|

|

|

|

|

|

|

|

|

4th of September 2011, Andrew came to visit me to pick up the car for

its beauty treatment. Great week end with a lot of frogeye talk

and much enjoyment.

On her way to

Archers Garage

....Can t wait to see her back.... |

. . |

|

|

|

5th of October and a few news from

Birmingham about the

restoration ...some good some no so good... When trying to

take off the fiberglass covering the B post on the drivers side

Andrew found some significant corrosion in it as well as

some damage.... It also looks like the car has a had a bump on the

B post

as well and that the previous owners re-fibreglassed over the top.

Also the shroud was so brittle that he broke in pieces...I guess

the good news is that a B-post is not really expensive and that

back shroud are readily available.....Also the remainder of the

structure such as the wheel arches look fine.

|

|

|

|

|

The Alfin have been shot blasted and look

really nice... I can' t wait to see them back on the car... |

|

|

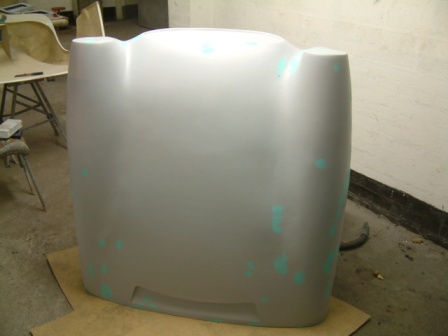

Andrew and team started to prep the bonnet to make a mould of it and cast

a new one....Also quite a

few bits and pieces such as back axle, engine went for an acid

dip...more news to come.... |

|

|

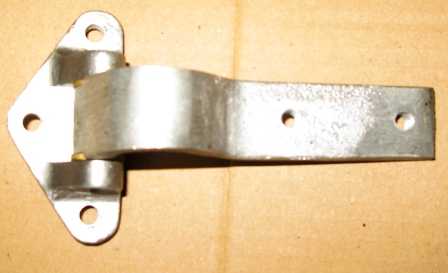

A few more pictures from Andrew received on the

18th of October 2011. The front of the car has been tidied up. The

old bonnet hinges have been taken off and will be replaced by

new ones. The front wings have been cut so to be

replaced by full aluminum ones. |

|

|

The shroud has now been fully taken off and so

has been the rusty b-post to be later replaced. |

|

|

Some items have been returned from their acid

bath . The rear brake back plates and my good old (non longer

rusty)

back axle. |

|

|

The wheels have been prepared to be shot blasted

and powder coated. I am not yet sure if I am going to use them

on 2080 PO or keep them as an extra set for my other car ( or

which more to come....) or else... The quarter elliptic have been dismantled

and acid dipped. they will later be rebuilt and painted. |

|

|

Andrew bought a 1275 , a few conrods and a

marina crankshaft to build the new engine for the car. They also

have been acid dipped. The engine when rebuilt will probably

a 1330 cc which should bring much "vavavoom" to 2080 PO.....Obviously

this will need to be notified to the DVLA. |

|

|

New lightened conrods and ARP bolts |

|

|

rocker cover, timing chain and front plate ready

to be painted |

|

|

Brake plates and blanking cover |

|

|

14th November 2011 a quick trip to agree on

details with Andrew and a good opportunity to take a few more

pictures of the work on progress.

The shell has now been striped out of its old GRP

shroud

|

|

|

Because the metallic frames which are embedded in the

old GRP doors seem to be rusty and will need much work and

hours to make them good I decided to replace them by full

aluminum doors . This aside being a cheaper and quicker option

has also the benefit of them being lighter

than the original doors. As for the old doors i will keep them

as a "souvenir" |

|

|

The hinges will also be changed

from steel to aluminum and bring a significant weight advantage. |

|

|

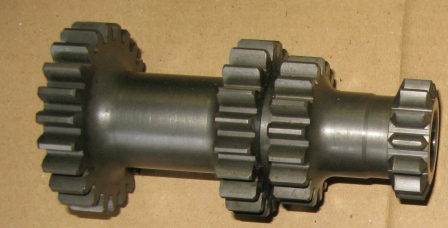

A few pictures of my set of straight cut gears

that will populate my ribbed case gearbox. Quite noisy but

supposedly near unbreakable. |

|

|

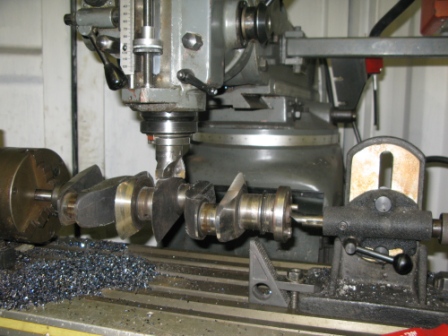

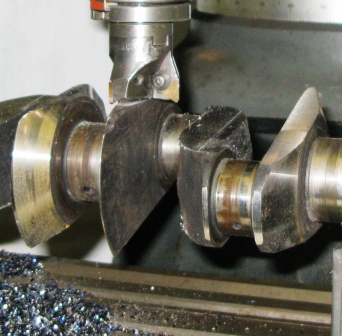

The crankshaft on the lathe being wedged to

lighten it and provide better RPM response... |

|

|

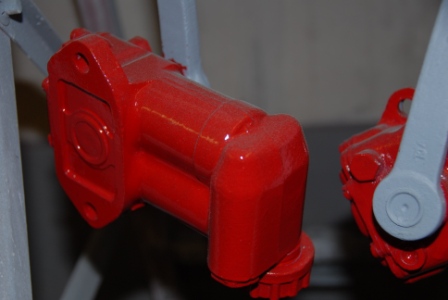

22/12/2012 and a few more pictures from

Birmingham. Andrew has started to repaint some items that were

acid dipped such as the back axle and some of the engine part

(to be shown later) . We decided to repaint the engine in Red

which should look nice in the bay which will be painted in

Healey blue. |

|

|

Unfortunately the seats are not cleaning nicely,

so we will probably get them re-upholstered using the old vinyl

covers as a template., The frames look ok and will be re-used. |

|

|

The shell has been shot blasted and etched

primed ready for some welding. Thankfully no bad surprises here.

Probably the outer sills to be renewed and welded as well as the

floor section under the driver. and the b-post on the

driver side. The rest should be minor stuff. |

|

|

|

|

|

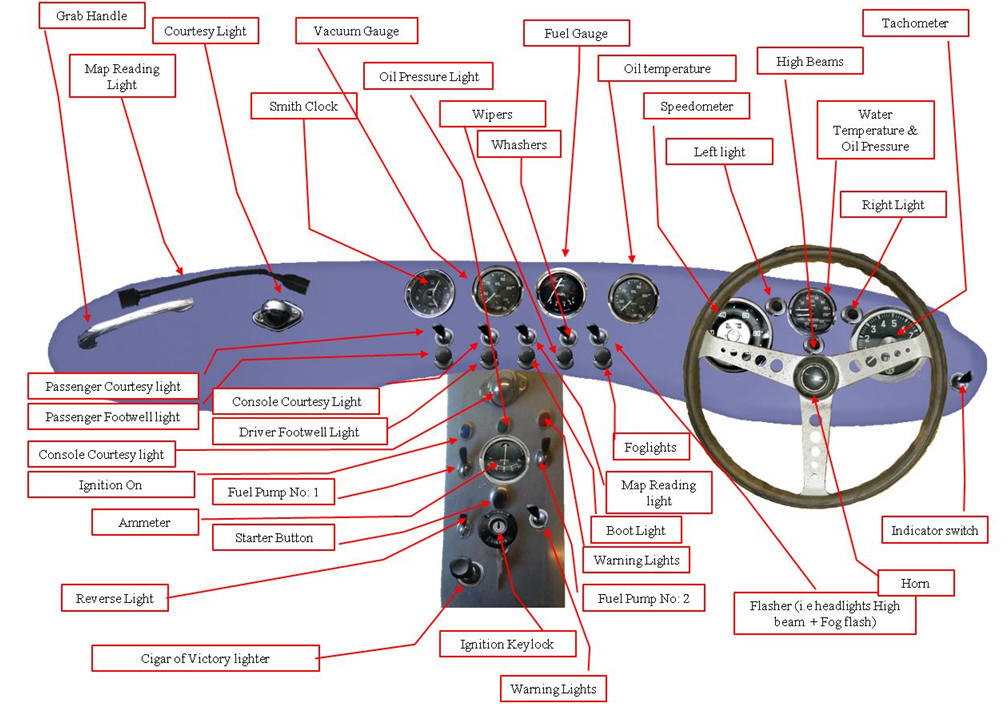

Ok time to start to be creative, now we are on

the rebuild phase we need to put some thoughts on what the car

will be like. This is a first draft of the dashboard and other

features of the car to be....probably will be

different at the end...but was fun to do..... |

|

|

|

|

|

Archer's Garage Team has been hard at work

replacing floor panels , sills and strengtheners.... |

|

|

|

|

|

|

|

|

Also the bonnet is soon to be

fully prepared so a mold

can be taken of it..... |

|

|

23/01/2012...Andrew has finished the welding on

the shell...

First picture got me worried as misread Andrew's email

as " all that could be salvage from your car..."...nearly had a

heart attack...obviously was "all that we could not salvage

from your car..."

Second picture is the right hand side sill |

|

|

left hand side A post of the car and aluminum

door in position |

|

|

H frame has been cut to accommodate the front

hinge. |

|

|

Driver underside panel replaced

bonnet hinge box removed & obstructed |

|

|

strengthener welded

secure on passenger side.

inside view of the driver side panel and strengthener . |

|

|

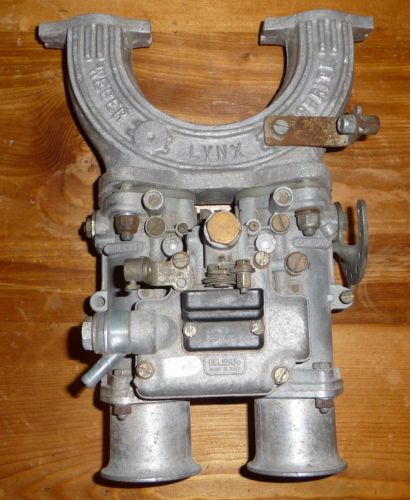

As per Ray English from down under who

produces the quintessential newsletter "Marque One"

"Made by LYNX of Sydney, Australia.

Lynx were one of the first companies in Australia to manufacture

their own speed equipment, and today their items are quite

sought after...." |

|

|

|

|

|

The bonnet is now fully

prepared for the mold to be made. |

|

|

The hinge boxes have been

removed and welded |

|

|

The bulkhead has been

reinforced where the engine steady bar will be fixed. |

|

|

The frame to which the

gasoline tank will be attached has been inserted in the

car. |

|

|

The aluminium doors are being

fitted. |

|

|

A few more pics from

Birmingham. The stanchions have been drilled to make the car

lighter.... |

|

|

front aluminium inner wings

have been attached and the scuttle has been welded and leaded |

|

|

B-post has been replaced |

|

|

aluminium door have been

fitted. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bonnet has been lacquered and

will be left to cure a few weeks before a mold is being taken of

it. |

|

|

The adjustable shock absorber

have been repainted and the oil will be changed later on |

|

|

The crankshaft is now

finished to specification. |

|

|

The flywheel has been

scalloped so as to reduce its weight without compromising its

integrity.

should give better acceleration potential to the car. |

|

|

Andrew and team have started

to work on the roll cage and have also installed the shroud. |

|

|

Making sure that we have

clearance so the hood fit over the roll cage. |

|

|

The backstay are in position

to be welded and two diagonal have been already welded....though

it looks like the drawing no 35 in the blue book ...I am still

not sure if this is right...the definitions in MSA the blue book

are really confusing.... |

|

|

The aluminium boot floor is

now painted in the gorgeous Healey Ice Blue and ready to be

assembled |

|

|

The Dan Dare Hardtop is being

prepared, so we can make a mold of it....quite tempted to keep

the same orange colour.....not ! |

|

|

|

|

|

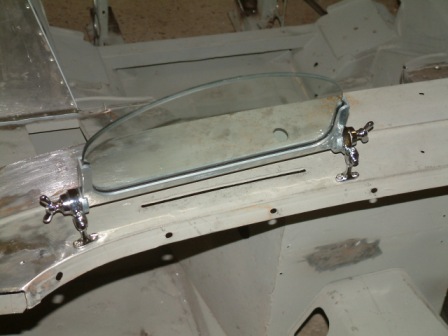

23/03/2012 great

progress at Archers Garage, the boot floor has been pop riveted, the

roll bar is being adjusted for the hardtop that will be painted

in old English white, the aero screens are fitted and the points

for the harnesses have been catered for.....can t wait.....It

suddenly start to look like a pretty car.. :)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I spent a bit of time preparing

what will be my dashboard..and here is the result. Just need

some tidy up and to be covered with fabric....just need the rest

of the car now ..... |

|

|

21/04/2012

The bonnet mould is being prepared. |

|

|

The shroud

has been cut so the roll bar can

fit. It will be sanded and prepared for painting. The hedge line

will be sanded away to git it a nice smooth and rounded look. |

|

|

The shell is now in the

painting boot and a coat of anti-grit has been applied all over

it. |

|

|

The roll bar was finally

reassessed and seem to be more in tune with FIA regulations. The

diagonal is removable |

|

|

|

|

|

The fuel cap has been polished with an

amazing result, I did not realise that some parts were made of

brass. |

|

|

15/05/2012

The underside and inside of

the shell has now been painted Healey blue ice, next step will

be to paint the shroud and bonnet and assemble them...the roll

bar will be painted mat black and the white flanks will be

painted later |

|

|

|

|

|

|

|

|

12/06/2012

The shroud has been assembled and the car has now been primed

ready for its color coat to be aplied. |

|

|

|

|

|

The aluminium doors have been

primed as well as the hood frame |

|

|

The

mould for the bonnet is partially finished, just need the wings

now.... |

|

|

04/07/2012

Nothing like the smell of paint in the morning

:) !!! |

|

|

|

|

|

|

|

|

Wings

and valance of the bonnet mould are done ... should be a new

bonnet coming out of that soon .... |

|

|

20/07/2012 another visit to Birmingham to talk upholstery and

others as well a getting a quick ride in a Sebring equipped with

a similar engine and straight cut that 2080 PO will sport

in a hopefully not so distant day... the straight cut is

clearly noisy and provide a good incentive to reach 4th gear...

:)

The quality of the work is great but it looks like quality

is an inverse function of time spent unfortunately....I think it is

now

unlikely the car will be ready for the Speed Trials after

all....I guess there is always next year...hopefully it will be

for the Good wood Revival so we can drive there in style.... :)

|

|

|

|

|

|

|

|

|

Now the

shell has just been painted in Healey ice blue, the white

strip will be painted probably next week and the car will then

be lacquered for protection and extra shine.... |

|

|

The roll

bar fit snugly, the aluminium rails have been sent to the

polisher. |

|

|

Can t

wait to see the filer cap and other chrome bit on the back of

the car, should be a nice contrast |

|

|

The

engine block has now been bored to its desired 1330cc |

|

|

31/07/2012

And now the white livery started to appear on the car.... how

great !!! Andrew now tells me the car soon will be on stands and

some of the mechanichal bits will be fixed to the car...still

won t quite cut it for the Speed Trials...I guess there is

always next year.... |

|

|

|

|

|

|

|

|

28/08/2012

Aluminium flanges have been fitted to the bonnet and the mold

should be finished in a week....guess it will be 2 or 3 weeks

from now till we can see the end result coming out of the

mold.... |

|

|

The

original seats frames have been re-enforced with a new

fibber glass coat and they will be sandwiched between two metal

plates for extra safety |

|

|

06/06/2012 The bonnet mold is at long last

completed....hopefully we should soon see a new bonnet coming

out of it to complete the bodyshell.... |

|

|

|

|

|

|

|

|

29/09/2012 at long last the mould is finished and assembled ... bonnet

in sight .. :)

|

|

|

Good

news, some cardboard boxes have appeared aroudn teh shell d some

parts have started to migrate to the shell..... |

|

|

Adjustable back on the shell but this time painted in red.... |

|

|

Aero

screens have been fitted to both side of the car. Originally

only the driver had one but I am

somehow more compassionate to my fellow passengers... :) |

|

|

9/11/2012

Front hub/brake assembly and anti-roll bar have been fitted |

|

|

The twin cylinder pedal box has been fitted

rear lights, badge and fuel cap have been fitted |

|

|

Anchor

points for the 5 points harnesses have been fitted |

|

|

The

aluminium backplate for the engine has arrived and also the

forged pistons to complement the

lightened con-rods |

|

|

The

piston have a nice recess which should flow gas better.

complete set of straight cut geras |

|

|

the LSD

and the competition half-shaft have also arrived, |

|

|

Front

hubs for the wire wheels |

|

|

The

aluminium trims have been polished and fitted to the car |

|

|

First

layer of gel applied to the bonnet mold.... |

|

|

seals

are being fitted to the car.

the windscreen has come back from polishing |

|

|

The

stantion have been polished and anodized but as pas weld points

remain apparent i have decided to have them painted blue as they

used to be when i took ownership of the car. |

|

|

10/12/2012... Brakes have been assembled on the Riley 1.5

back plates.. |

|

|

The

6-gallon tank has been painted black and the pipe and sender

unit has been fitted to the car.

dampers, engine mount steering rack clamps are now fitted.

|

|

|

The

crankshaft, flywheel and clutch have been assembled ready to be

sent to be balanced...

the original spare spark plugs holder is fitted... |

|

|

front

hub assembly nearly assembled... just waiting for the Brambo

disks |

|

|

The

electric loom is being fitted to the car... |

|

|

details

of the bonnet returns |

|

|

The

returns for the bonnet have been positioned on the mold. |

|

|

quarter

elliptics and dampers links have

been fitted |

|

|

The

windscreen pillars have been painted healey blue |

|

|

rear fog

light fitted and detail picture of rear

|

|

|

17-12-2012

Good news , the seats are back from the upholsterer and they

look gorgeous |

|

|

and so

do the dashboard and interior panelling |

|

|

18-12-2012

Christmas has arrived early for 2080 PO. At long last the bonnet

has come off the mould and to the delight of everyone in one

piece... ! |

|

|

|

|

|

|

|

|

11/01/2012

The bonnet is being fitted to the car...looking good |

|

|

|

|

|

22/05/2013 I have a

dashboard and a steering wheel ! At long last it starts to look

like a car ! |

|

|

The grid is being fitted to

the bonnet which has been primed ready to be painted. The

front hub are just missing the steering arms. |

|

|

Something is happening

under the bonnet , but still no engine in sight.... |

|

|

The seat have bee restored

in leather to the original pattern and look really great ! |

|

|

The bonnet catches have

been fitted to the bonnet. |

|

|

27/06/2013 A few more

bits have been fitted to the car. The painted aluminum doors

have also been fitted. |

|

|

The bonnet vents which were

re-chromed have been fitted. Note the inner scoops for which I

am very thankful to Ray English down under for sending me a

template of its original ones. They are made of aluminum and

will be painted later. |

|

|

The back axle has been

fitted to the car and there is no more work here than fitting

the wheels... The replica of the bonnet looks really great. I

can't wait to see it fitted to the car when it has been

painted... |

|

|

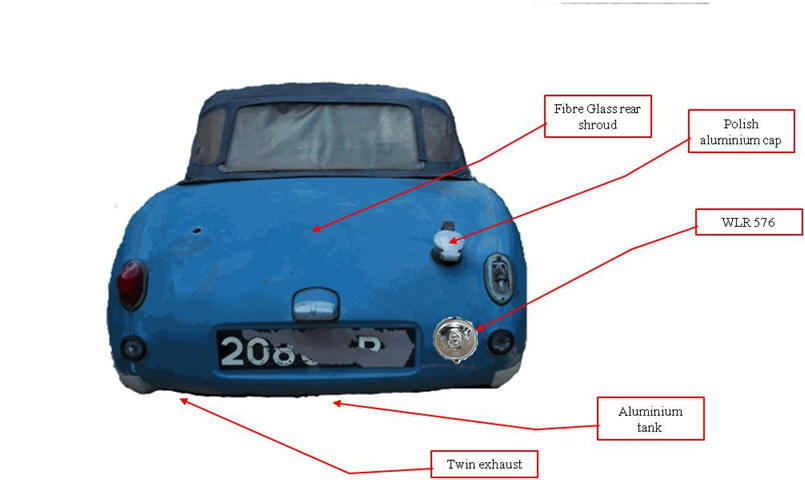

The color scheme of the car

looks really good and is faithful to the original livery....it

will be a very pretty car for sure.... |

|

|

I am really happy with the

inside of the car. The carpets should soon be fitted as well as

the seat and the roll-bar...and hopefully the engine so I can

drive it down to the GoodWood Revival.... |

|

.jpg) |

On the right hand side are the replica & restored badges that

will soon adorn the bonnet again... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|